Capricorn RC Lab TE02 Build and Review

Introduction Back in 2006 I took up RC model car racing as a hobby and raced 1:10 scale electric touring cars until winter 2009. ...

https://www.thercracer.com/2014/04/capricorn-rc-lab-te02-build-and-review.html

Introduction

Back in 2006 I took up RC model car racing as a hobby and raced 1:10 scale electric touring cars until winter 2009. I had some success winning Cotswold Model Car Club's championship three times along with finishing second (TC) & third (M-Chassis) in a local indoor clubs winter championships. I also had a go at off-road racing winning a few 1:18 micro open meetings along with the BRCA national series 2WD championship in 2009, and on my return to racing in summer 2013 achieved second in a local 1:8 Rallycross club championship.

Previously I raced several different Tamiya/TRF touring cars but this time round I felt like a change. After looking at lots of different cars I chose the Capricorn-RC Lab-TE02. Capricorn are new to electric racing but have been long established as a well-regarded premium nitro on-road manufacturer. The TE02 from what I can ascertain is either an upgraded version of the Titan ARC R10-2013 or a very accurate tribute with parts being interchangeable between the two.

Unboxing

A really nice touch is the plastic tool/parts box that the TE02 comes supplied in, another is the instruction manual being included on a Capricorn-RC branded USB memory stick. Things like this really help to positively differentiate one manufacturer from another!

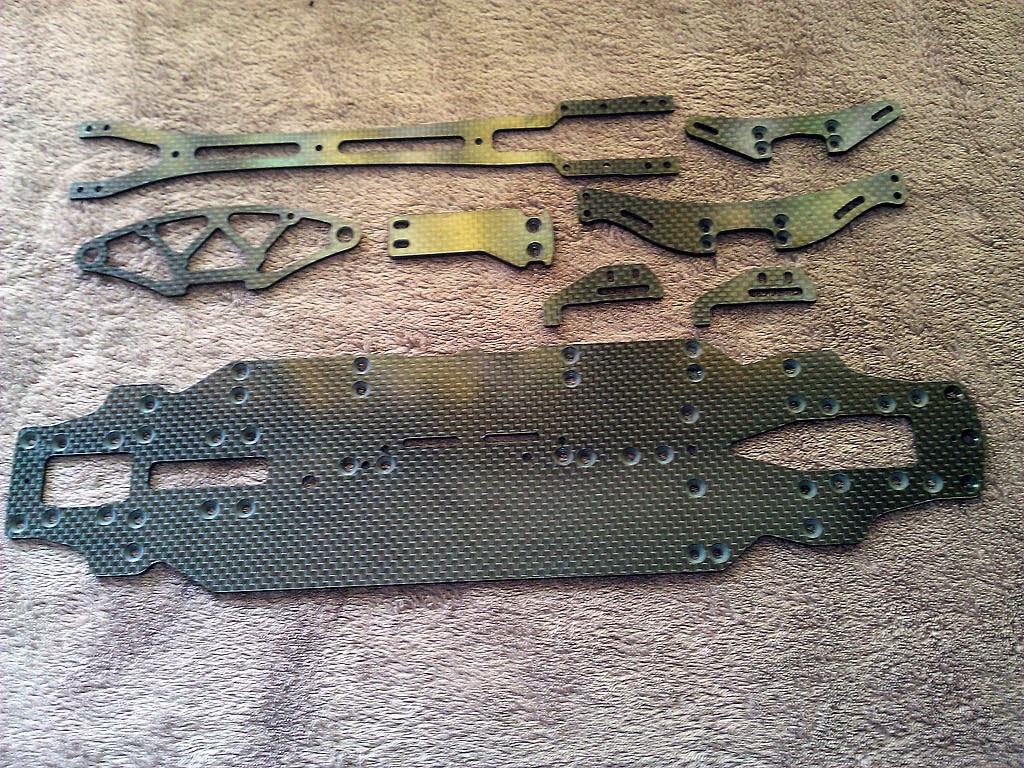

Carbon

The Capricorn-RC Lab-TE02 features a 2.25mm carbon chassis along with a 2mm top deck, 3mm carbon low profile shock towers and a carbon bumper support, battery retaining clamps and floating servo mount plate.

All the parts look well made and the narrow main chassis plate is milled slightly below where the motor would be. Minimal cut-outs give a clean look and a nice feature is the additional set of holes for shorty LiPo battery packs. The chassis and top deck have holes along the centre line for optional posts to be fitted to reduce flex in high traction conditions.

After lightly bevelling the edges of the battery clamps to reduce the change of the cell tape being cut I sealed the edges of all the carbon parts with Cyanoacrylate glue (super glue). Sealing isn't essential but I've always done so and never had any delamination problems. I use a 'Bostik Superglue Precision/Ultra Pen', so much easier and faster than other methods I've tried and results in a lovely smooth finish.

Bulkheads

Attaching the drive train to the chassis are some lightweight red anodised machined aluminium bulkheads, along with a floating motor mount. The red makes a positive change from the usual blue, black, purple and silver seen on other cars and handily matches my Team EDS tools for that all important pro driver look.

Bumper & Body Mounts

A foam bumper sandwiched between a carbon top and plastic bottom plate connected by two aluminium strengthening columns protects the front of the chassis from crash damage.

The front body shell mounting columns/posts are supported by the bumper whilst the rear columns are connected to the shock tower. The body shell sits on top of plastic hats which can be positioned vertically on the columns using metal pins in the pre-drilled holes for maximum flexibility and fine tuning.

Diff &Spool

The Lab-TE02 like most current 1:10 touring cars has a solid/fixed axle front spool and rear gear differential. The advantage of having a spool at the front instead of a diff is the improved drive accelerating out of corners; the downside is increased push (understeer) on corner entry plus more strain on the shafts and outdrives.

The spool features an aluminium axle, Kevlar reinforced plastic 38 tooth pulley and machined lightweight steel outdrives. The use of blade-less steel outdrives is a huge bonus in terms of durability over plastic or aluminium designs. A drop of oil in the bearings and thread lock on the three pulley bolts is all that's needed to assemble.

Ball differentials were the norm when I last raced touring cars but due to the constant maintenance required to retain a smooth action they have been replaced with miniature oil-filled geared units. The viscosity of the oil may be changed to infinitely tune the differential action to suit the track conditions!

The diff case and pulley (38T) are again Kevlar reinforced plastic along with plastic internal gears and steel outdrives. Red anodised aluminium eccentric bearing retainers are used on both the front spool and rear diff to adjust belt tension and are more resilient to compression than plastic items.

I pre-tapped the gear case holes with a spare 2.5mm screw, then using circular motions lightly sanded the surface of the case to remove any burrs and to gain a flat even finish. This along with 'Team Associated Green Slime' on all the rubber seals is strongly advised for a leak free differential. 1000 CST oil is supplied with the kit which I used after first pre-building the diff without oil to check for any roughness, which happily there wasn't. For my efforts I've been rewarded with a super smooth, leak free, rear differential.

Center Layshaft

An aluminium axle, 112 tooth spur gear and a pair of Kevlar plastic 19 tooth pulleys make up the center layshaft assembly. Via the motor pinion gear it provides drive to the front spool & rear differential using 510 and 189 tooth 3mm drive belts respectively. Happily only a single 0.1mm Tamiya shim was required to remove any unwanted side float from the layshaft assembly!

The layshaft axle is supported by rubber sealed ball bearings at each end which are pressed onto the layshaft/motor mount towers. I found the bearings to be a tight fit so using 1200 grit wet & dry paper lightly sanded the red anodising to achieve a perfect fit. The parts were correctly machined but the anodising process was enough to affect the tolerances of mine. The 112 tooth 64 DP spur gear looks very much like a RW Racing item which is great news, however I intend to race in the 13.5T & 17.5T Blinky classes so this will be changed to smaller 70 tooth 48 DP spur to increase durability and obtain the ratios needed.

Drive Shafts

Double cardan joint front and 44mm rear constant velocity (CVD) drive shafts are included with the Lab-TE02 kit. The double joined front drive shafts reduce steering related chatter/vibration compared with other designs. Both front and rear shaft & axle assemblies are of steel construction so vastly more durable than lightweight aluminium items and are supported within the hubs by dual rubber sealed ball bearings. Red anodised aluminium wheel hexes, held in place by a tiny 2x5mm screws are supplied to attach the wheels.

The rear CVDs use plastic blade protectors to reduce wear on the diff outdrives. I found them a real struggle to attach to the drive shaft pins and is something I've not encountered before. A quick email to UK distributor CPD Racing advised to clip one side of the blade protectors in followed by the other. I still couldn't using my fingers stretch the stiff plastic into place, so having clipped one side in I pushed the blade hard against a table to attach the other. This technique worked a treat and hopefully the plastic blades will be very hard wearing.

Oddly my front drive shafts came assembled but not the rear! I disassembled and cleaned all the parts with WD40 before coating the internal pins and inserts with 'Tamiya Anti-Wear Grease' and re-assembling. A 'G' shaped clip is used to retain the pins instead of a grub screw resulting in a much smoother functioning joint.

Independent Double Wishbone

The Lab-TE02 uses the familiar independent double wishbone design of suspension on all four corners to support the chassis. The upper arms are adjustable turn buckle linkages with open style ball end cups for ease of maintenance, whilst the lowers are sturdy plastic wishbones moulded from a hard graphite reinforced plastic.

The arms are the same left to right and may be flipped over to offer alternative lower shock mounting positions. Wheelbase is adjusted by varying the size of the supplied spacers in front or behind the wishbones. Droop is set using a small set screw going through the wishbone as per most other touring car kits. The wishbone inner hinge pins are supported on 5mm balls which sit inside recesses within the suspension brackets. I used a small amount of anti-wear grease on these balls for a smoother action and increased service life.

The suspension brackets, again red anodised aluminium, are of a split design towards the centre of the car to aid chassis flex and a single piece type at the outer ends. Shims may be placed below the mounts to adjust roll centre, the kit setting being 1mm all-round.

Shock Absorbers

The Lab-TE02 features 'big bore' coil-over shock absorbers with threaded oil-filled dampers to adjust ride height and smooth ti-nitride coated shafts. They're shorter in height than conventional shocks to lower the cars centre of gravity and the fatter shock body cylinders keep the oil volume comparable.

The 3-hole 1.1mm pistons and lower spacer/shim are machined rather than moulded plastic so require no re-working and a 'Quad-ring' labyrinth seal holds the oil in. I put plenty of 'Team Associated Green Slime' on the seals to keep them lubricated and reduce friction plus potential leaks from the shock shafts. 500 CST silicone oil is supplied with the kit which I used along with the yellow (0.30) front and green (0.28) rear springs.

Anti-Roll Bars

1.4mm front and rear anti-roll (sway) bars are included with the Lab-TE02 kit and how they are mounted to the bulkheads is sure to be copied by others in time.

The bars are ingeniously supported on twin flanged ball bearings which results in a silky smooth action with no side to side play. Adjustable links connect the roll-bars to the wishbones and again use open ball cups to aid maintenance.

The bars are ingeniously supported on twin flanged ball bearings which results in a silky smooth action with no side to side play. Adjustable links connect the roll-bars to the wishbones and again use open ball cups to aid maintenance.

Steering Rack

A twin arm steering rack in common with most touring cars is used for the Lab-TE02. The main steering plate is red anodised aluminium whilst the arms are graphite reinforced plastic and supported by rubber shielded ball bearings. The main focus of innovation are the small aluminium plates used to quickly and precisely adjust the Ackerman, 8.5 being the default kit setting.

The turn buckle ends I pre-tapped with a spare screw before assembly along with some Associated black grease on the threads to make adjustment easier. Any screws not threaded into plastic I secured with a small amount of blue liquid thread lock. I also fitted a mixture of Losi and Team Associated foam dust covers to the ball connectors, whilst not essential especially with open ball cups they help keep dust and dirt out of the ball joints to reduce wear and stickiness.

Floating Servo Mount

Floating servo mounts are a recent update fitted to many newer competition level cars. The servo is suspended from the chassis using a centrally mounted bracket, the benefit being more consistent chassis flex left to right and the servo being isolated from many of the vibrations travelling though the chassis. Capricorn have gone with a combination of red anodised brackets and a carbon plate to make up the servo mount, which weighs 14 grams including all the required fixing screws. Handily the inner bracket also doubles up as an antenna mount!

The parts to the right of the above photo are the adjustable clamps used along with fibre cell tape to retain standard or shorty sized LiPo battery packs to the chassis.

Servo Horn

The Lab-TE02 includes three rather sturdy looking servo horns to fit 23, 24 or 25 spline servos Being an un-sponsored full retail paying racer I've opted to fit a 'Tamiya Hi Torque Servo Saver (#51000)' to protect my servo from possible damage. The Tamiya servo saver has a strong spring to reduce any loss of sensitivity and is the same item as supplied with Tamiya's TRF touring car kits.

Electrics

I built my Capricorn Lab-TE02 up with KO Propo radio/electrics I already had from previous projects. They're a few seasons out of date now but still great quality and electronic speed controller's lack of boost timing doesn't matter for blinky class racing. Connected to them are my old AMB transponder and a new Reedy Sonic 17.5 turn brushless motor complete with a short 70mm sensor lead to keep the wiring tidy. The main motor and battery wiring is Muchmore Racing 12 AWG Silver Silicone.

With the Lab-TE02's narrow chassis installation of the electronics was tight but thankfully due to the use of a low profile servo everything has fit neatly on the main chassis plate without having to resort to stacking the transponder or receiver on top of the servo.

- Transmitter : KO Propo EX-10 Helios 2.4GHz SS

- Receiver : KO Propo KR-409S 2.4GHz SS 4-Channel Micro

- Servo : KO Propo PDS 2413 ICS Low Profile Fast Digital

- ESC : KO Propo VFS-1 BMC v1.5 (with ROAR Spec Blinky firmware)

- Transponder : AMC-RC Dp

- Motor : Reedy Sonic Mach 2 540 17.5T Brushless

- Batteries : Reedy 7000mAh 65C 7.4V 5mm Competition LiPo

Finishing Touches

With indoor racing in mind I've opted for a Protoform P37-R body shell which the manufacturer says is ideally suited to rubber tyre racing on tight technical carpet or asphalt tracks. I always mount and cut my body shells before painting as I find it easier to correctly position them, plus avoids any damage to the paint when sanding the edges smooth. After cleaning the shell in soapy water, drying, then masking off the windows I sprayed it my usual 'Tamiya PS-1' white.

I finally fitted Sorex XG-28JB tyres with blue inserts and Revlite 24mm wide wheels which are the current favoured combination for carpet racing, the blue inserts being firmer than yellow ones used for asphalt tracks.

My completed Lab-TE02 weighs 1358 grams ready to race including the standard weight Protoform P37-R body shell, radio/electrics, LiPo battery (318g), transponder (7g) and Sorex XG-28JB wheels & tyres (100g). The assembled out-of-the-box kit excluding all of the above was 525 grams.

Test Run & Verdict

With the build just completed the car has only had a very brief test run at a local indoor track, primarily to setup to radio system and check everything was working okay. I was impressed by the car's handling, in particular its nimbleness with plenty of steering on offer. The drive train was quiet, smooth and the car progressive in acceleration and braking.

Set-up

Pros and Cons

Positives: The overall quality of the Lab-TE02 looks to be on par with touring car kits from the top established manufacturers. I liked how the car went together with no sanding, reaming or excessive shimming of the parts being necessary. Many parts which would be essential/desirable options are included with the kit such as the narrow chassis, floating servo mount and double cardan front drive shafts, plus innovations like the ball bearing mounted anti-roll bar, Ackerman inserts and big-bore shock absorbers.

Negatives: The instruction manual is a little lacking in detail in some places and includes no setup sheets (see capricornrc.com) or guides. I also had a few screws which were incorrectly threaded or with miss-formed (possibly non-metric) heads which is a shame considering the high quality of the rest of the kit.

Overall

On first impressions I'm very happy with my choice of car and look forward to racing it competitively indoors and outdoors this summer.

This car looks to be an exciting new contender in 1/10 onroad RC. There are a lot of innovative refinements on this car and the initial testing shows a lot of promise.

Contributor John Timberlake

This car looks to be an exciting new contender in 1/10 onroad RC. There are a lot of innovative refinements on this car and the initial testing shows a lot of promise.

Contributor John Timberlake